Investment Casting

We are a professional and decades experienced Foundry (investment Casting) with ISO/IATF16949, PED TRD-100 approved and 10204 3.1B, ASTM, MIL certified from Taiwan. Also, we have established new Foundry with in-house Machining shop in Guangdong Province, China, this huge foundry owns 172,000 square feet plant area, 107,000 square feet for building area, with 300 employees for 200 tons capacity output monthly. The almost about 80% of products have been delivered to USA, Europe and Japan. The modern facilities for the production and QA system have been qualified from DT, NDT inspections by Spark Spectrometer, Tensile Strength, Charpy Impact, Hardness Tester, Coordinate Measuring Machine, Optical Comparator, Metallurgical Analysis Equipment etc.

Hitech-Metal machine shop is able to provide CNC-Lathe machines, Center-Machines, Milling machines, Tapping machines for varied machining requests, and for which as polishing, plating, heat treatment, assembly, testing also would be available.

ISO/IATF16949 / TRD-100 CERTIFICATE

Hitech Metal has its own precision casting foundry whose production chiefs have decades experience in investment casting, techniques. Our foundry is equipped with the most modern production equipment and quality control facilities for certified quality from ISO/IATF16949, PED TRD-10 standards approved.

EDM for Pattem

TOOLING DIE SHOP

Hitech-Metal was formed by a group of engineers who control all aspects of production from design to finished product, with quality inspection at every stage. Hitech-Metal is equipped with many sets of electrical dischargers, machine-center and lathe machines for tooling die making.

Wax Molding Room

WAX MOLDING FULL COLLOIDAL SILICA PROCESS(FCP)

The Investmen Casting Foundry factory is equipped with 12 sets of injection machines with capacity for 14sets of injection port for castings with flanged valve size up to 6” and weight up to 35 kg.

Wax Clustering Assembly

Conveyer for Shell Molding

CERAMIC SHELL MOLDING

The foundry factory is equipped with a conveyer for slurry dipping and sanding up to 7 coats, and utilizes big slurry mixing bucket for large castings up to 60 cmdiameter, temperature and humidity would be recording ensure that ceramic shell could be strong enough.

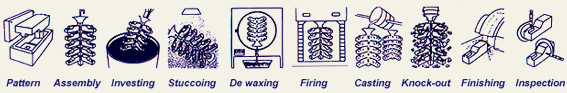

WHAT IS AN “INVESTMENT CASTING”?

The investment casting " Lost Wax " process require an aluminum die. Wax is injected into this aluminum die to produce a pattem that is an exact replica of the part to be produced. For every casting, a wax pattem must be manufactured. The patterns are clusterted around sprue and repeatedly dipped into an agitated vat of ceramic and alloowed to dry. After a shell thickness of approximately 3/8" (5~7 coats) been built; the molds are dewaxed by either flash firing at high heat (1400oF) or autoclaving (pressure and stem).

The hollow shells are then preheated to 800 ~ 200oF depending on the alloy to be poured and the molten metal cast immediately into the hot shell. After cooling the ceramic is vibrate and blast off the metal parts discarded. The balance of the cleaning operations (cut off, grind, heat treat, straightening, blast) are straight forward and final castings' quality to be inspected.

INVESTMENT CASTING PROCESS

WHAT IS AN “INVESTMENT CASTING”?

- Complicated Configuration

- One Piece Molding

- Precise Dimensions

- Fine Surface Finish

- Minimize Parts Machining

- Reduce Costs For Production Programs.

COMPLEX SHELL PROCESS (CSP)

For saving the cost, we can offer the complex shell casting for economical request, the shell in first to third coat isa made by colloidal silica binder process, the coat of 4th after could be replaced by sodium silicate binder process, its production progress is speedy to meet high volume production.

SODIUM SILICATE SHELL PROCESS (SSP)

The shell of SSP could be speedy all molding by sodium silicate binder for high volume production, that ensure to make cost down for your production program for higher casting up to 100kg.

Wax Mold

Complex Shell

Sodium Silicate Shell

Casting from CSP, SSP

Conveyer for Shell Molding

BURNIGN AND CASTING

The big wide 70 cm dual doors burning furnaces and 3 sets of US/VIP High Frequency Induction Furnaces controlled by our professional engineers and analyzing the chemical elements concentration of alloy before pouring, means only 22 minutes are spent for each firing batch, providing high speed, high quality casting production.

SHOOT BLASTING, CUTING, CLEANING FINISH

Hitech-Metal has equipped 7 sets of varied heavy, belt-moving, high pressure shot blasting and polishing machines ensure that big to miniature parts, critical small hole and corner parts would be cleaned effectively.

Hitech-Metal Investment Casting technology has been applied in the production of:

- Aerospace

- Architectural Hardware

- Automotive Vehicles, Bike

- Bearings & Seals

- Business Machines

- Candy Machinery

- Chemical Processing

- Computerware & Peripherals

- Consturction, Machinery

- Cental Instruments

- Electrical, Electronic Equip.

- Enviromental Equip

- Exploration Drilling Equip

- Fastening Machinery

- Firearms, Weapons

- Food & dairy Equip

- Forming & Fabricating Equip

MATERIALS

- Ferrous Base Alloys: Carbonsteel, High Speed Steel, Tool Steel etc.

- Cast Iron, Ductile Iron, Alloy Cast Iron

- Nickel Base Superalloys: Monel, Hastelloy, Inconel, Incoloy, Nimonic Alloys etcl

- Aluminium and Copper Alloys.

PRODUCTS

- Castings of industrial Valves, Fittings, Pumps.

- Propellers, Impellers, Marine, Engine Parts.

- Turbine, Heat Exchanger, Furance Parts.

- Machinery, Building, Computer Parts, Housing

- Pneumatic, Hydraulic, Stamping Tools Parts

- Auto, Vehicle Parts, Motortcycle, Motor Parts

- Medical, Sport Equipment Parts and Artiffical Joints

- Flowmeter, Instrument Parts, Thermocouple Parts

Auto Parts

Tool Parts